|

| July 16, 2013 | Volume 09 Issue 27 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Mechatronics:

Spherical vehicle with balancing drive module

Not every idea can be implemented in a useful manner, but as we all know an experiment will often create basic knowledge for later applications. One example is this spherical vehicle that was created for a bachelor's thesis in Germany. GIGATRONIK Stuttgart GmbH, a medium-size company specializing in automotive electronics and information technology, sponsored the mechatronics demonstrator, which balances autonomously on a hollow mobile ball.

The project shows the possibilities of modern mechatronics, combining sensor technology, rapid data processing, and actuators into a functioning unit. Highly dynamic, electronically commutated miniature drives from FAULHABER (sold through MICROMO in North, Central, and South America) also show their true potential as an interface between electronics and mechanics. The balancing sphere now serves as a GIGATRONIK demonstrator at fairs and recruiting days.

To create the ball, complex position control, in combination with fast mechanical implementation of the necessary commands, represented a challenge to both developers and the integrated components.

When quick reflexes are a necessity

Like a human on two legs, a spherical vehicle has an unstable "stance." It requires continuously active readjustment in order to maintain a position in the room. The balancing act must be carried out very quickly, even reflexively -- for the faster the reaction, the more minor necessary corrections are and the better the stability of the device.

In the case of the balancing sphere, a vehicle equipped with electronics, three electric motors, and a rechargeable battery balances on a ball. The dimensions of the vehicle are approximately 30 x 30 x 15 cm, and it has a net weight of approximately 5.5 lb. Shifts in the center of gravity of the vehicle allow the ball to easily roll along on the surface. Like a tight-rope aerialist, the vehicle is forced to balance out these rolling movements through corresponding counter-movements. To this end, a seamlessly integrated inertial sensor measures acceleration, rotation rates, and the force of the Earth's magnet field on the electronic circuit board of the prototype controller "GIGABOX gate."

The actual control is modeled with Simulink, transferred via a Simulink target by means of autocode generation in C-code, and integrated into the controller as a real-time task. From measured data, the software computes the actual status of the overall system. The system can be seen as a three-dimensional, inverse pendulum. The pitch and roll angles are determined by a position scanner. Two PD controllers provide the necessary pulses for the stabilizing drive. These pulses are then converted by three omnidirectional drive wheels, each offset at 120 deg in a circle, into mechanical motion relative to the spherical surface.

Highly dynamic and accurate

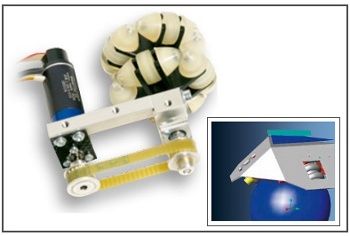

Only highly compact motor units can be used to drive the wheels. The required dynamics narrow the options to electronically commutated motors. The optimal choice proved to be three 20-mm-diameter brushless DC servomotors that sport integrated encoders. Diameter-compliant gearing with a speed reduction of 14:1 supplements the drive package. With it, the small 20-W drive can supply up to 0.7 Nm for short periods in order to control the position. A toothed belt reduction further boosts the torque to the wheels. The high efficiency factor on the part of the motors (70 percent) and gearing (80 percent) enables the use of smaller re-chargeable batteries. The smaller dimensions also improve the vehicle's quick reactions to position commands. The three drive units are continuously deployed independently from one another, thus converting the control commands into mechanical propulsion.

A further advantage for fast, dynamic corrections is the fact that miniature motors, especially electronically commutated variants, are generally able to withstand considerable overload for short periods of time. Due to the device's low volume, the heat radiating to the surface is comparatively high; the thermal capacity of the materials offers a further thermal buffer. The high efficiency of the unit, i.e. comparatively low power dissipation, enables such a high level of energy transfer above the rated output. In connection with the low level of moving mass, this performance virtually predestines the use of EC drives for highly dynamic functions. This is particularly the case when small installation spaces and/or very low inertial masses, e.g. on the tip of cantilever arms or robotic arms, are necessary.

Even ostensibly playful functions can contribute to the solution of problems. Small prototypes that can complete complex tasks in real time, such as this example of the active balancing on a ball, are cost-effective research objects. Miniature drives with auxiliary modules, such as encoders, gearing, and also integrated controllers, enable not only inexpensive implementations for experiments but are also suitable for use in professional applications. FAULHABER's extensive assortment of motors enables a customized solution for every drive task.

Want more information? Click below.

Published July 2013

Rate this article

View our terms of use and privacy policy